Order Entry

Create a Customer Order From a Quote

System Location: Data Entry > Orders > Orders

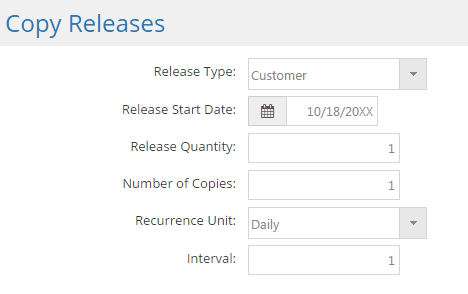

This topic provides details on how to create an order for customer releases from a quote, covers the basics of editing information on a job, and shows how to process an order.

For more information see Order Entry.

- Go to the blue Data Entry tab, open the Orders dropdown menu, and select Orders.

- Click New (located at the top of the page.)

Select Quote

Select Quote

Process the Order

Process the Order