Job Processing

Order Processing

System Location: Data Entry > Orders > Orders > Process / Unprocess

Processing an order assigns a Job Number and calculates requirements for each (unprocessed) line item present. The behavior of the system when orders are processed depends largely on the Company Maintenance option labeled Automatically Post Parts as discussed later in this topic.

Production related work cannot begin on a line item in JobBOSS2 until it has been processed and received a Job Number.

Processing An Order

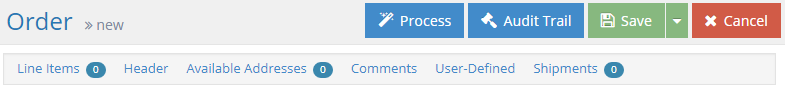

The Process button displays in either of the following situations:

- When a new order is being created

- When additional line items are added to a previously processed order

In either situation, clicking Process causes the following to take place for every unprocessed line item present on the order:

- Each line is assigned a Job Number.

- Processed line items are referred to as jobs and represent individual production runs.

- Every job must have a unique Job Number.

- Each job has its own set of production related details.

- Production related work cannot begin on a line item until it has a Job Number.

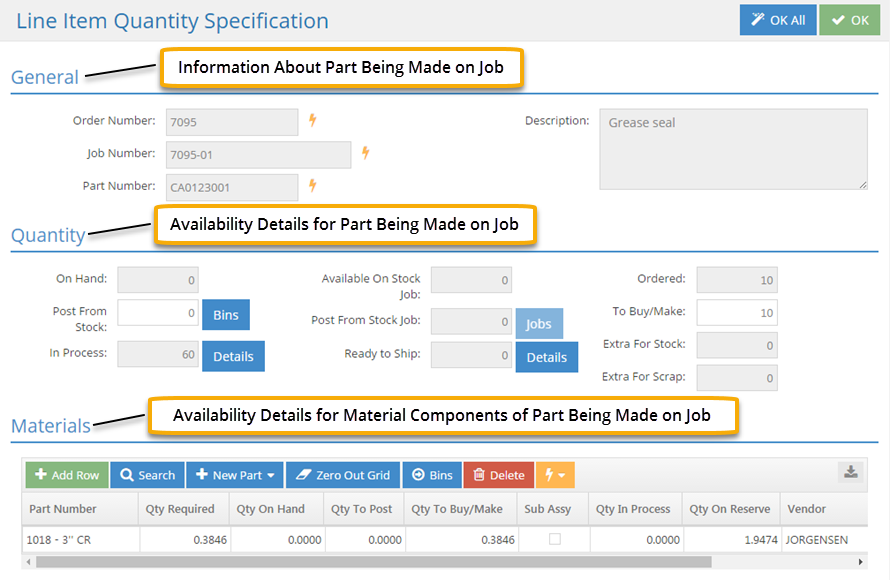

- Job requirements are calculated.

- Material requirements are based off of Bill of Material (BOM) items.

- When the unit used for estimating purposes is the Stocking Unit (EA, BAR, FT, etc.):

- Quantity Required = Quantity Ordered * Quantity Needed to Make 1 Unit

- If the calculation results in a decimal value, be aware that only whole units of material can be stocked / pulled from inventory.

- When the Unit used for estimating purposes is P (Parts per Stocking Unit):

- Quantity Required = Quantity Ordered / Number of Parts Per Stocking Unit (ROUNDED UP TO NEAREST WHOLE VALUE)

- When the unit used for estimating purposes is the Stocking Unit (EA, BAR, FT, etc.):

- Service requirements are created from Vendor Steps located on the Routing of the Estimate.

- Material requirements are based off of Bill of Material (BOM) items.

The system only calculates job requirements if an Estimate is used in the creation of a job. If an Estimate is not used, job requirements and routing information will have to be added to the job directly.

- If the option to Automatically Post Material is selected in Company Maintenance, the system will make material available to post during processing; otherwise it assumes material requirements will be filled later and simply creates the Jobs and their related requirements regardless of availability.

Posting Material

As previously noted, the ability to post material when a Job is processed depends on how the option to Automatically Post Parts is configured in Company Maintenance.

For more information see Company Maintenance.

![]() System Behavior: Automatically Post Parts Selected

System Behavior: Automatically Post Parts Selected

![]() System Behavior: Automatically Post Parts NOT Selected

System Behavior: Automatically Post Parts NOT Selected

Make to Order or Make in Advance?

Perhaps the most important consideration is when manufactured parts, including subassemblies, are made. If they are made in advance and placed into inventory for immediate shipping, leaving this option enabled is the most logical choice. The reason - once Jobs are created, posting manufactured parts from inventory does NOT fulfill the need for the Quantity Ordered.

If parts are made to order, the decision to use this option may depend on other factors.

Timing of Order Processing

When material is posted to a job it is immediately considered to part of Work in Process (WIP) and is no longer included in On Hand Quantities. If a job is processed but work does not begin on it for an extended amount of time, having material posted to it could lead to inefficiencies in material usage.

Personnel Considerations

Is the person that enters orders qualified to determine what material is used? If not, perhaps having someone else use the Fill Job Requirements Utility once jobs are created would work better.

Given the impact this can have on the production process, it is worth taking the time to consider how to best use this setting for each environment.

Unprocessing An Order

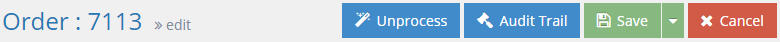

The Unprocess button displays once all the line items on the order have been processed and assigned Job Numbers.

When available, clicking Unprocess removes assigned Job Numbers and places each line item back into an unprocessed state. This makes it possible to change the Quantity Ordered for one or more line items and then have the system re-calculate requirements by clicking Process again.

The option to unprocess an Order is only available if no production related actions have been taken on any Job present on the Order.

An Order cannot be unprocessed once any of the following has taken place with regards to any Job:

- Production related records have been created, including:

- Time Tickets

- Purchase Orders (Received or not)

- Miscellaneous Job Costs

- Any quantity has been shipped

- Any quantity has been canceled or a Job has been closed

The only transaction that can be "undone" is the posting of material so long as nothing else has been done. The assumption here is that material can be placed back into inventory if work has not begun.

If an Order cannot be unprocessed, quantities can still be changed; however related requirements would have to be manually adjusted.

Requirements are calculated ONLY when a Job is processed.