Base Tables

Tooling Maintenance Codes

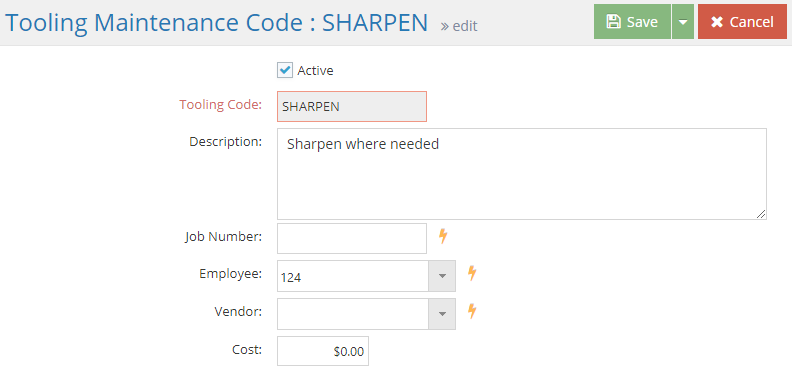

System Location: Settings > Base Tables > Tooling Maintenance Codes

Tooling Maintenance Codes provide a means to keep track of maintenance previously performed or scheduled to be performed on parts set up as Tooling Items (Saw Blades, Drill Bits, etc.). When the Quality Application is available, these codes are used to complete tooling maintenance records.

For information about the Quality Application, please contact sales at 1-800 525 2143.

The Record Header located at the top of the page indicates which specific record has been selected and for what purpose (new, edit, quick view) and displays record specific Action Buttons (discussed below.)

For more information see User Interface.

Action Buttons

Save (button)

Save Button Details

This button is used to close the record and save any changes that have been made while it was open. In addition, the dropdown button allows you to Save and:

- Close - close the open record.

- New - open a new blank record.

- Print - print any of the reports related to the open record.

Cancel (button)

Cancel Button Details

This button is used to close the record without saving any changes that may have been made while it was open. If this button is used after a change has been made to the record, the system prompts to verify whether the record should be closed without saving the changes.

Answering "Yes" to the prompt closes the record without saving the changes.

Answering "No" to the prompt leaves the record open.

Back to Top

An asterisk [*] indicates a required field.

Active (checkbox)

Checking this box indicates the maintenance code is actively used.

- Only active codes display as options when scheduling maintenance

- Remove check for codes that are no longer used

*Tooling Code

This is the "short name" assigned to the maintenance code by the user.

- Must be unique

- Can be up to 12 alpha-numeric characters in length

- Should indicate the type of maintenance performed

Description

Use the description to provide additional information about what needs to be done during the maintenance process.

- Appears on Tooling Maintenance Code Navigator and various reports for reference

Job Number

A job number can be associated with the code as a means to track when the maintenance is performed and how long it takes if they are performed internally.

- Not required, but if used it must be a valid job number

- Can also provide a way to track costs associated with internal maintenance

- Consider creating a job for each maintenance code

Employee

An employee can be assigned to the maintenance code to identify who will likely perform the maintenance if done internally.

Vendor

A vendor can be assigned to the maintenance code if it is performed by an outside entity.

Cost

This field would be used to represent the expected cost of externally performed maintenance or of associated material.

Back to Top