Base Tables

Operation Codes

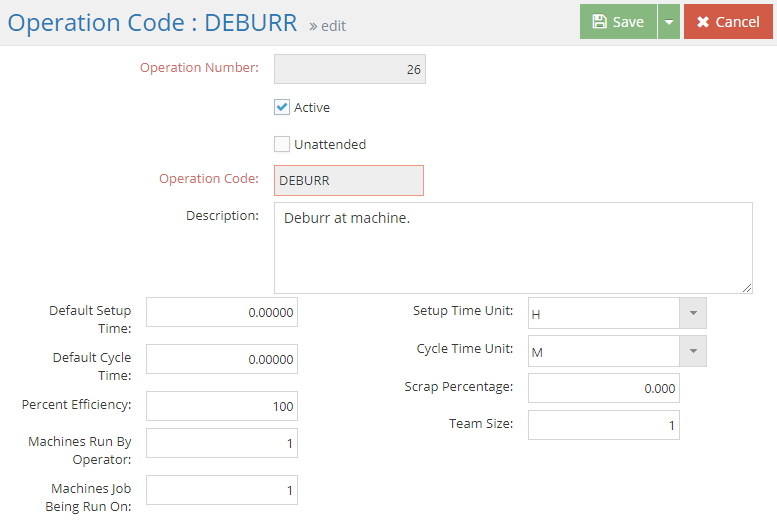

System Location: Settings > Base Tables > Operations

Operation Codes provide a means of populating default values for work steps found on estimates and jobs to help identify the type of work being performed at a given Work Center.

Record Header - Operation Codes

Record Header - Operation Codes

The Record Header located at the top of the page indicates which specific record has been selected and for what purpose (new, edit, quick view) and displays record specific Action Buttons (discussed below.)

For more information see User Interface.

Action Buttons

Save (button)

Save Button Details

This button is used to close the record and save any changes that have been made while it was open. In addition, the dropdown button allows you to Save and:

- Close - close the open record.

- New - open a new blank record.

- Print - print any of the reports related to the open record.

Cancel (button)

Cancel Button Details

This button is used to close the record without saving any changes that may have been made while it was open. If this button is used after a change has been made to the record, the system prompts to verify whether the record should be closed without saving the changes.

Answering "Yes" to the prompt closes the record without saving the changes.

Answering "No" to the prompt leaves the record open.

Operation Code Details

Operation Code Details

An asterisk [*] indicates a required field.

Active (checkbox)

Checking this box indicates the operation code is actively used.

- Only active codes display as options on routers

- Remove check for operation codes that are no longer used

*Operation Number

This numeric identifier can be assigned automatically by the system or entered by the user.

- Must be unique

- Can be a maximum of five digits in length

*Operation Code

This is the "short name" assigned to the code by the user.

- Must be unique

- Can be up to 12 alpha-numeric characters in length

- Should indicate the type of work performed during the stated operation

Values from this point forward will be used to automatically populate routing steps the operation code is assigned to, but any of the values can be edited in the step details.

Description

Information here is intended to provide details regarding the work associated with the operation.

- Prints on the Job Traveler (WORK Step Type) or Purchase Order (VEND Step Type)

Unattended (checkbox)

This setting indicates whether an employee is expected to be physically present during the estimated amount of cycle time associated with the operation.

- When this value is set to "Yes" it is assumed that no one will be physically present while work is being done on the part(s). The result is:

- Burden costs will be estimated / captured for both setup and cycle times

- Labor costs will be estimated / captured for setup time ONLY

- When this value is set to "No" it is assumed that someone will be physically present for at least some portion of the time while work is being done on the part(s).

In situations where the employee will be physically present for some, but not all, of the amount of time work is being done on the part(s), the Machines Run By Operator setting (below) can be used to account for how much time the employee is expected to be absent.

Default Setup Time

This value represents the estimated amount of time (in terms of the selected Setup Time Unit) it will take to prepare a work center that is associated with the operation.

Setup Time Unit

Setup Unit works in conjunction with Setup Time to define how long it is expected to take to prepare a work center that is associated with the operation. Options include:

- Hours

- Minutes

- Seconds

Default Cycle Time

This value represents the estimated amount of time (in terms of the selected Cycle Time Unit) it will take to perform the work detailed in the Description for one unit of a manufactured part.

The use of Cycle Time in the Routing Grid is different than its use within the Scheduling Application. From a scheduling context, Cycle Time refers to the total real time "clock hours" required to complete a scheduled task for the entire quantity being worked on.

Cycle Time Unit

Cycle Time Unit works in conjunction with Cycle Time to define how long it is expected to take to perform the work detailed in the Description for one part. Options include:

- Hours

- Minutes

- Seconds

- Pieces Per Hour (System uses value to calculate how long it will take to make one unit in terms of an hour)

Machines Run by Operator

This numeric value represents the number of work centers (machines) the employee performing the work is capable of running at one time for the selected operation.

- The value entered must be a whole number

- If greater than 1, the result is a reduction in estimated labor costs for setup and cycle time

Machines Job Being Run On

This numeric value represents the number of like Work Centers (machines) expected to be used at the same time to perform the work for the selected operation.

- The value entered must be a whole number

- When it is greater than 1:

- Estimated cycle time is decreased since the same number of estimate machine hours are expected to be spread across multiple Work Centers

- Estimated setup time is increased since multiple Work Centers need to be prepped for use

- In order for scheduling to be accurate, the Capacity Factor of Work Centers that are used in this way needs to match the value entered here.

Scrap Percentage

This numeric value represents the percentage of manufactured parts that are expected to be scrapped during the selected operation.

When entering percentages in JobBOSS2, enter the value as a "standard" number instead of the decimal equivalent. For example, if the value should be five percent, simply enter "5" as opposed to ".05"; the system will automatically convert the value accordingly.

- When greater than zero (0), the system will calculate (when Jobs are processed) how many additional units of the manufactured part need to be made to compensate for the anticipated scrapped pieces

- At a minimum one (1) additional unit will have to be made

- Scrap percentages are cumulative, meaning a 1% Scrap Percent on each of 5 steps will result in a MINIMUM of 5 additional pieces being made since the system is expecting at least one piece to be scrapped on each step.

- Given the cumulative nature of scrap percentages, it is recommended to leave the value at 0 on operation codes and assign a single Scrap Percentage for an entire router as they are created.

Percent Efficiency

This numeric value represents how efficiently the work detailed in the Description can be performed on the selected operation in terms of scheduled cycle time.

When entering percentages in JobBOSS2, enter the value as a "standard" number instead of the decimal equivalent. For example, if the value should be five percent, simply enter "5" as opposed to ".05"; the system will automatically convert the value accordingly.

- The value can be a decimal number

- When less than 100%, cycle time (at the Job Level) will be scheduled to take longer to complete than the amount of cycle time estimated here

- EXAMPLE: If Efficiency Percent is set at 80% in the Estimate, scheduled cycle time will be increased by 20% on any Job created for the selected part

- This assumes that Efficiency Percent is not edited at the Job Level, which is an option. In that case, scheduled cycle time will be based on the Efficiency Percent designated there.

Team Size

This numeric value represents the number of employees it is estimated to take to perform the work detailed in the Description of the selected operation.

- The value entered must be a whole number

- The system multiplies the amount of estimated cycle time by the value entered here

- If greater than 1, the result is an increase in estimated labor costs for cycle time

- Setup time is not affected by this value.