Utilities; Import Bill Of Materials

Use the Import BOM (Bill Of Materials) Utility

This utility is used to import part information from a spread sheet that has been saved as a ".CSV" file for the purpose of creating a Bill Of Material (BOM). Depending on the format of the file, the information can be used to create a single or multilevel BOM.

Importing the .CSV File

Importing the .CSV File

Once an import file has been created using one of the formats provided below, the information can be used to populate the Materials grid of an existing Estimate (manufactured part).

Parts included in the spreadsheet that are not already defined in JobBOSS2 will be added as new parts based on the following criteria:

- Parts with a Vendor Code associated will be added as Inventory Items (purchased parts.)

- Parts without a Vendor Code associated will be added as Estimates (manufactured parts.) This is only applicable for multilevel BOM imports.

System Location: Data Entry > Quoting > Estimating

- In the Navigation Sidebar, click the Data Entry button.

- Open the Quoting dropdown menu.

- Select 'Estimating'.

- Click 'Import.'

- On the Import BOM screen, click 'Upload BOM.CSV File.'

- Select the .CSV file that contains the desired information.

- Click 'Open.'

- The utility populates the materials grid with the information from the spreadsheet.

- Click the 'BOM Level' Header to sort the part information by BOM Level to make it easier to see which items go together.

- See the 'Format' sections below for additional information regarding how this information is displayed.

- Verify / edit 'Part Number.'

- By default the utility populates the 'Part Number' field with the file name and will need to be edited if this is not the desired name for the Estimate to be created.

- If a Part Number is entered for an existing part, the utility provides a warning prompt to verify that the Materials information should be replaced when the utility is closed.

- Determine whether undefined parts in the grid should be added to JobBOSS2 as parts.

- Placing a check in 'Permanently Add Part Numbers' causes the utility to add any parts located in the import file to JobBOSS2 as defined parts if they are not already present in addition to being listed on the BOM of the part being created.

- Parts with a Vendor Code associated are added as Inventory Items (purchased parts.)

- Parts without a Vendor Code associated are added as Estimates (manufactured parts.)

- Leaving 'Permanently Add Part Numbers' blank causes the utility to add the parts in the import file to only the BOM of the part being created.

- Parts already defined JobBOSS2 that are listed as material components in the import file are not affected by the utility regardless of how this setting is configured.

- When importing a multilevel BOM, the Revision Level value of sub-assembly items in the spreadsheet MUST match the Revision Level of the existing part in order to be recognized correctly. For additional information, see the Format Of Multilevel BOM Spreadsheet section.

- Placing a check in 'Permanently Add Part Numbers' causes the utility to add any parts located in the import file to JobBOSS2 as defined parts if they are not already present in addition to being listed on the BOM of the part being created.

- Click 'OK.'

Format Of Multilevel BOM Spreadsheet

Format Of Multilevel BOM Spreadsheet

The following table lists the Field Names (which become the worksheet's column headers), the column used for that field, and associated values for each entry that are found in the spreadsheet used to import a multilevel Bill Of Material.

- Row 1 (one) of the spreadsheet is used for column headers / field names and will not be included in the import.

- While not included in the import, it is strongly recommended that values are provided in row 1 for the user's benefit when entering BOM details.

The import starts on line two (2) of the spreadsheet and assumes the presence of a header line, which is ignored.

| Field Name (Row 1) | Column | Values |

|---|---|---|

| BOM Level | A | Required (See Below) |

| Part Number | B | Required |

| Description | C | Not Required |

| Revision Level | D | Not Required (See Below) |

| Quantity | E | Required (See Below) |

| Unit Of Measure | F | Not Required: Will Default to EA if not provided |

| Material Unit Cost | G | Not Required |

| Material Unit Price | H | Not Required |

| Alternate Part Number | I | Not Required: Optional Field |

| Part Weight | J | Not Required |

| File | K | Not Required |

| Drawing Designation | L | Not Required |

| Notes | M | Not Required |

| Vendor Code | N |

Not Required (See Below) |

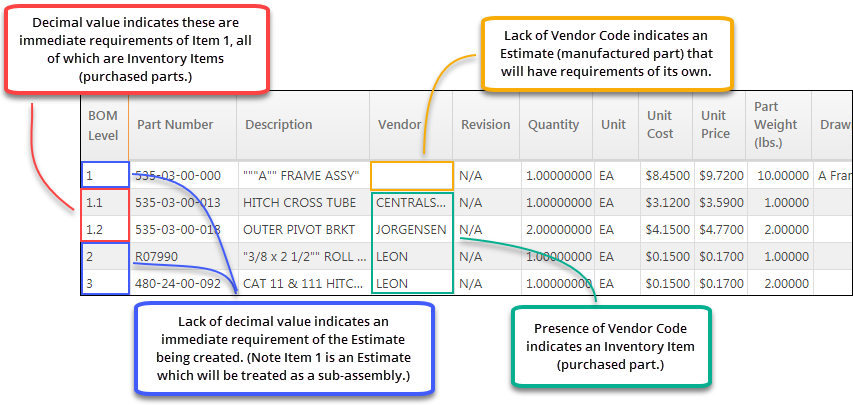

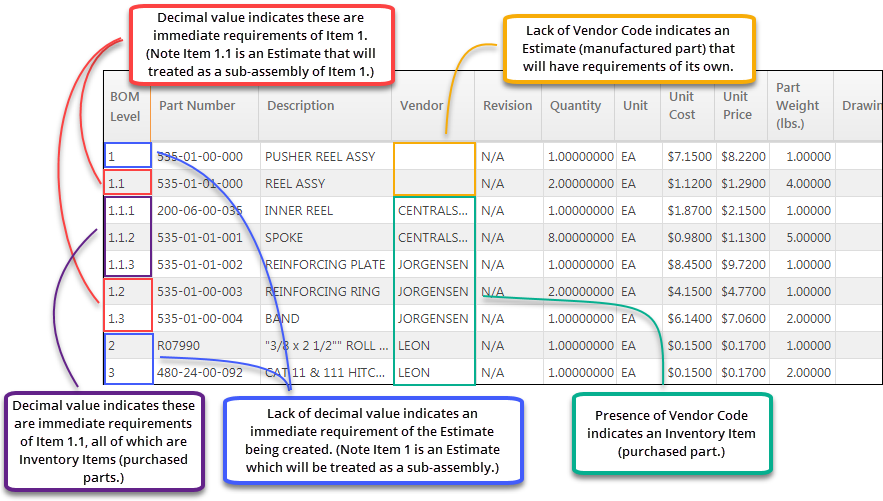

BOM Level: Required. It is the key to knowing the hierarchy of part levels.

- BOM Level = 1.1 is a subpart of BOM Level = 1

- BOM Level = 1.1.1 is a subpart of BOM Level = 1.1

Revision Level: When left blank in the spreadsheet, the system provides a value of “DEFAULT.”

In order for parts in the spreadsheet to match existing parts JobBOSS2, the Part Number and Revision Level values in the spreadsheet must be populated and must be the same as the part JobBOSS2, otherwise the utility will treat the part on the spreadsheet as a freeform part. This is true even if the Revision Level of the existing part is listed as DEFAULT.

Quantity: Required. Tells JobBOSS2 the quantity of the listed part needed to make one of its associated main part.

Vendor Code: If this is blank the utility assumes the part is an Estimate (manufactured part.)

- If the listed Vendor does not exist JobBOSS2, the utility will display a prompt to that effect, providing the opportunity to correct the issue prior to importing.

Format Of Single Level BOM Spreadsheet

Format Of Single Level BOM Spreadsheet

The following table lists the Field Names (which become the worksheet's column headers), the column used for that field, and associated values for each entry that are found in the spreadsheet used to import a single level Bill Of Material.

- The import starts on line one (1) of the spreadsheet and automatically places the values in the correct location in the utility grid.

- The column headers / field names listed below should not be included in the spreadsheet.

| Field Name (Row 1) | Column | Values |

|---|---|---|

| Part Number | A | Required; Cannot be duplicated in spreadsheet |

| Item Number | B | Required; Numeric Value; See Below |

| Alternate Part Number | C | Not Required |

| Product Code | D | Not imported |

| Vendor Code | E | Not Required; See Below |

| Quantity | F | Cannot be 0 or blank; See Below |

| Part Weight | G | Not Required |

| Part Notes | H | Not Required |

| PLACEHOLDER | I | Not imported; Value must be 1 |

| Description | J | Not Required |

| Unit Cost | K | Required; Can be zero ($0.00); Must have US dollar sign ($) |

Item Number: Determines the order in which items are displayed on the BOM

Vendor Code: If this is blank the utility assumes the part is an Estimate (manufactured part.)

- If the listed Vendor does not exist JobBOSS2, the utility will display a prompt to that effect, providing the opportunity to correct the issue prior to importing.

Quantity: Required. Tells JobBOSS2 the quantity of the listed part needed to make one of the associated main part.